Implementing smarter manufacturing practices has unlocked significant benefits across our workshops and operation centres. The shift from manual to digital processes, and the integration of wireless communications and artificial intelligence (AI) within our Land Defence Systems’ platform manufacturing division, has resulted in improved speed, elevated precision and enhanced safety.

Our integrated approach to smart manufacturing emphasises holistic, end-to-end enhancements for seamless operations and maximum efficiency. |

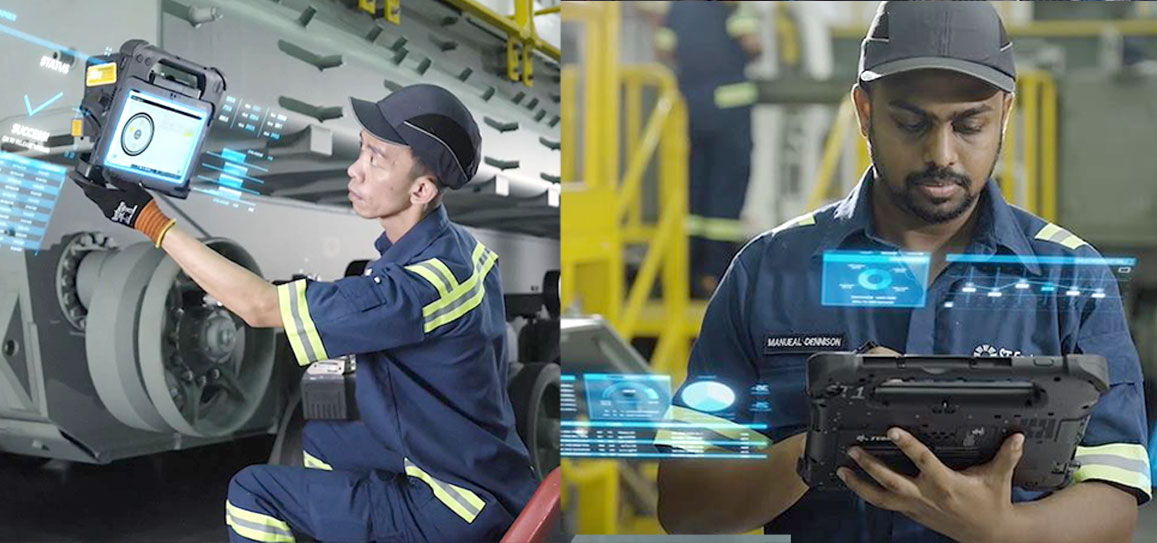

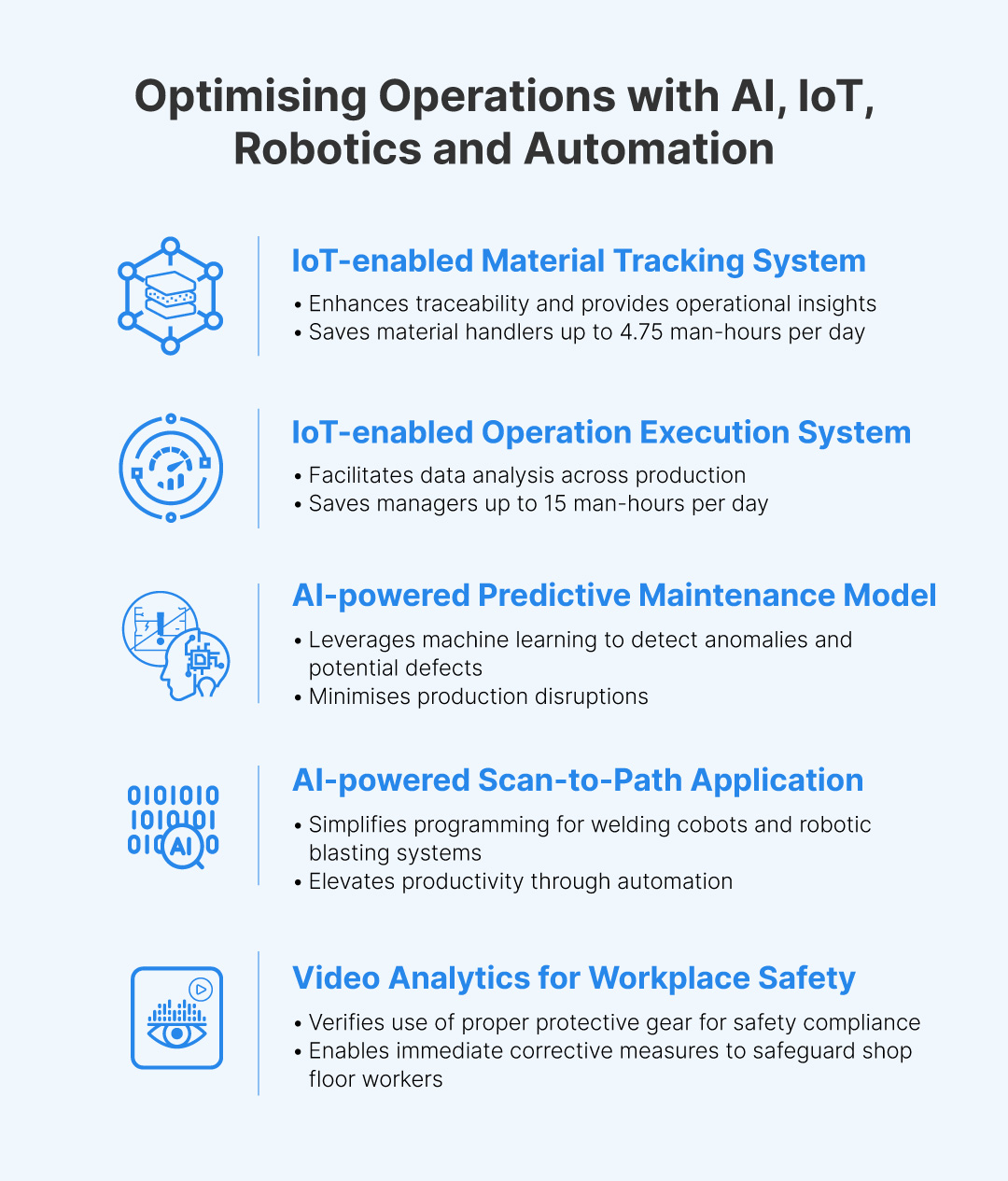

Industrial Internet of Things (IoT) has been a game changer for us, enabling us to capture useful insights about our operations. With IoT-based solutions like our Material Tracking System (MTS), we have access to real-time data that enhances traceability, optimises logistics, and simplifies workflow management.

By leveraging Radio Frequency Identification technologies and IoT-enabled scanners integrated into our SAP enterprise systems, our material management team enhances tracking of material usage and movement. Previously, material handlers had to scan items individually, but with the MTS, they can now scan entire bins at once, saving up to 4.75 man-hours per day. This interconnectivity also gives our operation centres real-time visualisation of on-the-ground activities, enhancing supply chain visibility and improving delivery times.

The ready access to data and real-time analytics has fundamentally transformed our approach to decision-making and operations management, revamped traditional methodologies, streamlined strategic planning, and redefined operational efficiency.

At the core of this is the Operation Execution System (OES), integrated into our Industrial IoT devices to monitor every stage of the production process - from plate-cutting and fabrication to machining, assembly and final quality assurance. The OES tracks production performance data such as lead times, manufacturing process data, quality data, and man & machine utilisation, among other information. Managers can then use insights gained through data analysis, to make informed decisions that optimise operations. Additionally, the OES has drastically reduced manual task updates, saving up to 15 man-hours per day in our operations.

To support this overall digital architecture, we developed a centralised data warehouse in our operation centre to store all the structured data generated. The data-driven insights gathered here enable us to make decisions that streamline processes, improve efficiency, enhance production sustainability, and ensure higher quality.

Machine learning and AI, particularly Generative AI, opens up a myriad of opportunities for innovation. For example, our implementation of a predictive maintenance model for machining operations uses machine learning to detect anomalies and potential defects, facilitating pre-emptive maintenance that minimises delay and costs from production disruptions. This gives our production engineers valuable insights to enhance operational sustainability and deliver greater value to our customers.

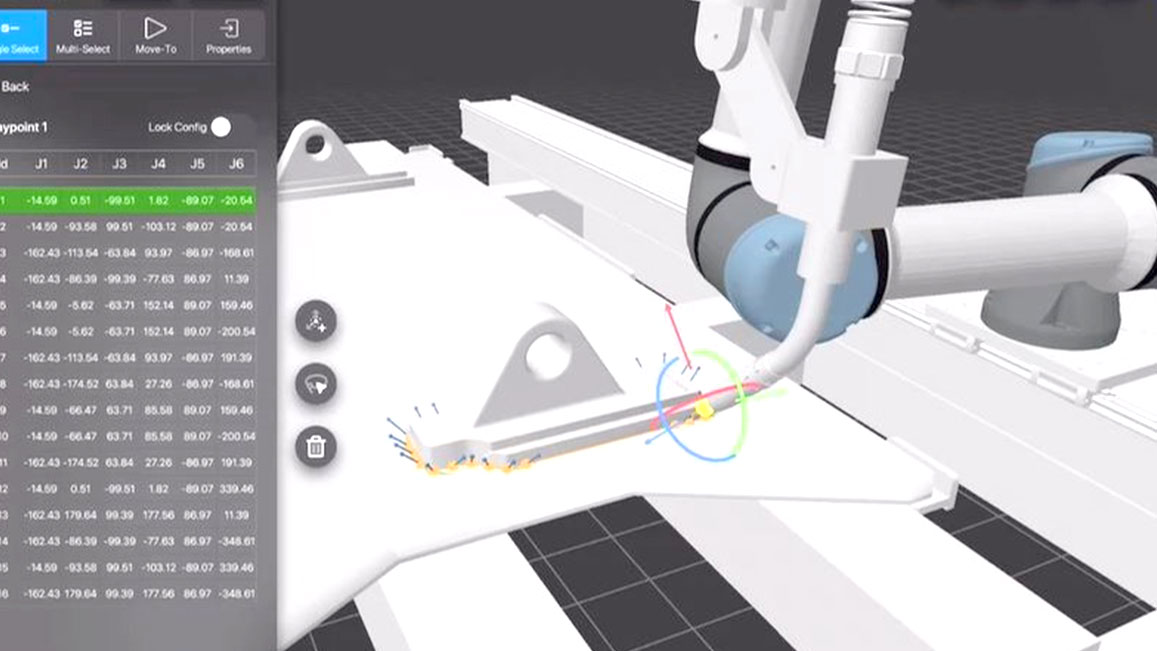

Today, AI-driven robotics and automation are enabling us to reap productivity gains in our dynamic manufacturing process. Our AI-powered Scan-to-Path application automatically generates robot motion based on parameters input by our engineers, simplifying programming for welding cobots and robotic blasting systems.

Beyond using AI for machine data analysis, we are leveraging video analytics for intelligent surveillance on the shop floor to help pinpoint any safety compliance issues such as verifying proper protective gear on technicians during hoisting operations. This enables immediate corrective measures and greatly improves workplace safety. Additionally, we are collaborating with AI experts to develop GenAI tools such as chatbots for knowledge management.

As we explore other promising technologies, our manufacturing team remains focused on reinforcing our foundations in big data and AI. Our integrated approach to smart manufacturing emphasises holistic, end-to-end enhancements for seamless operations and maximum efficiency. This journey towards smarter manufacturing underscores our commitment to harnessing technology and innovation, highlighting the transformative power of digitalisation.

As we continue to adopt and embrace advanced capabilities, we aim to set new standards in our work and by extension, deliver greater value to our customers.

Copyright © 2025 ST Engineering

By subscribing to the mailing list, you confirm that you have read and agree with the Terms of Use and Personal Data Policy.